A swimming pool pump manual is essential for understanding installation‚ operation‚ and maintenance. It guides users through troubleshooting‚ safety measures‚ and optimal performance‚ ensuring efficiency and longevity of the system.

Overview of Pool Pump Operation

A pool pump operates by circulating water through the filtration‚ heating‚ and sanitization systems. It creates suction to draw water from the pool‚ pushes it through the filter‚ and returns clean water. Proper operation ensures clear water‚ efficient sanitation‚ and optimal system performance. Continuous or programmed runtime‚ depending on the pump type‚ maintains water quality and prevents stagnation. Regular maintenance‚ as outlined in the manual‚ is crucial for longevity and energy efficiency.

Importance of Following the Manual

Following the pool pump manual is crucial for ensuring safety‚ efficiency‚ and longevity. It provides specific instructions for installation‚ operation‚ and maintenance‚ helping users avoid common errors. Proper adherence prevents electrical hazards‚ optimizes water circulation‚ and reduces energy costs. The manual also guides troubleshooting and maintenance tasks‚ ensuring the system runs smoothly. By following the manual‚ users can prevent potential issues‚ extend the pump’s lifespan‚ and maintain a safe and efficient pool environment consistently.

Installation and Wiring Instructions

Proper installation and wiring of your pool pump are vital for safe and efficient operation. Always follow the manufacturer’s guidelines to ensure correct electrical connections and system setup.

Step-by-Step Installation Guide

Begin by preparing the installation site‚ ensuring it is level and near the pool. Mount the pump securely‚ following the manufacturer’s anchor kit instructions. Connect the plumbing lines to the pool and filter system‚ ensuring all fittings are tight. Next‚ connect the electrical wiring according to the manual’s specifications‚ using the correct voltage and GFCI protection. Finally‚ test the pump by turning it on and checking for leaks or unusual noises to ensure proper operation.

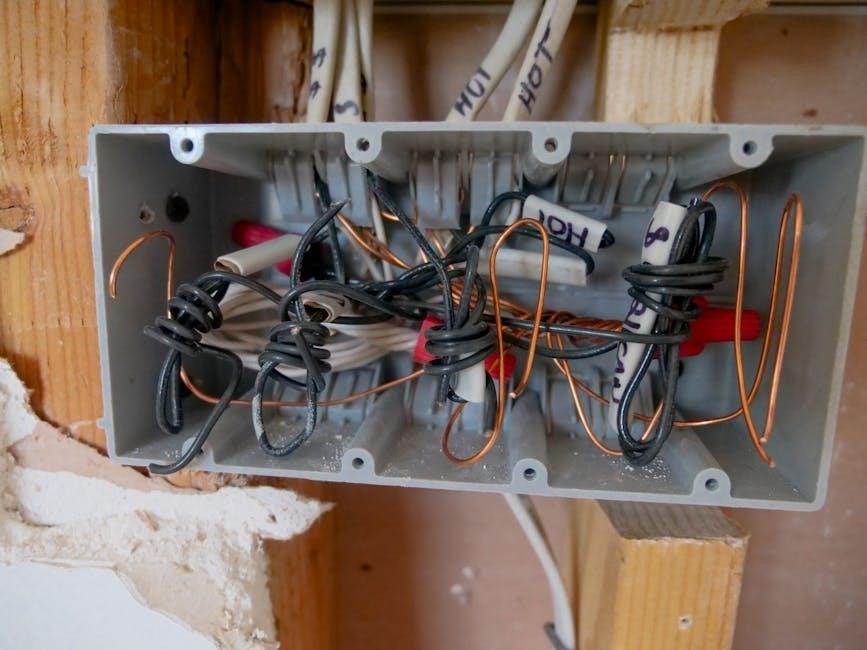

Electrical Wiring Requirements

Ensure the pump is wired according to the manufacturer’s specifications and local electrical codes. Use a GFCI-protected circuit to enhance safety. Verify the voltage rating matches the pump’s requirements‚ typically 120V or 240V. Connect the wires securely‚ following the manual’s wiring diagram. Hire a licensed electrician if unsure. Always turn off power before servicing. Refer to the manual for specific wire gauge and connection details to prevent electrical hazards and ensure proper operation.

Priming and Starting the Pump

Priming ensures air is removed from the system for proper water flow. Follow manual instructions to prime effectively‚ then start the pump and monitor its operation closely.

How to Prime the Pump Effectively

Priming the pump removes air pockets‚ ensuring proper water flow. Turn off the pump‚ open the air valve‚ and fill the housing with water. Replace the valve and turn the pump on at low speed. Check for leaks and monitor for smooth operation. If air bubbles persist‚ repeat the process. Always follow the manual’s specific instructions for your pump model to avoid damage and ensure efficient performance;

Initial Startup and Testing

After priming‚ start the pump at low speed and check for smooth operation. Monitor the pressure gauge and ensure water flows evenly through the system. Listen for unusual noises and inspect for leaks. Allow the pump to run for 30 minutes to test performance. Adjust settings as needed and refer to the manual for specific startup procedures. Proper testing ensures the pump operates efficiently and prolongs its lifespan.

Filter Maintenance and Cleaning

Regular filter maintenance is crucial for optimal pump performance. Inspect and clean the filter as recommended‚ ensuring proper water flow and system efficiency. This helps extend the pump’s lifespan.

Regular Filter Cleaning Procedures

Regular filter cleaning is essential for maintaining water quality and pump efficiency. For DE filters‚ remove and soak grids monthly. Sand filters require backwashing every 1-2 weeks. Cartridge filters should be hosed down monthly and replaced as needed. Always turn off the pump before cleaning. Proper cleaning prevents clogs‚ reduces pressure‚ and ensures optimal water circulation. Neglecting maintenance can lead to poor filtration and increased energy consumption. Follow manual guidelines for specific filter types.

When to Replace Filter Media

Replace filter media when efficiency drops or manufacturer guidelines specify. For DE filters‚ grids typically last 3-5 seasons. Sand filters need new sand every 5-7 years‚ while cartridge filters may require annual replacement. Look for signs like reduced water clarity‚ increased pressure‚ or poor circulation. Regular inspections can prevent premature wear. Always follow the manual’s recommendations for your specific filter type to ensure optimal performance and water quality. Avoid delaying replacements‚ as it can strain the pump and degrade water condition. Proper disposal of old media is also advised.

Troubleshooting Common Issues

Identify common issues like overheating or low flow. Refer to the manual for error codes and solutions. Check for blockages or worn parts regularly to ensure smooth operation.

Diagnosing Pump Overheating

Check for blockages in the inlet or impeller‚ as debris can restrict water flow. Ensure proper water flow rates and correct pipe sizing. Verify motor load and voltage match specifications. Overheating may indicate worn seals or bearings. Regularly inspect and clean the pump basket. Follow manual guidelines for motor cooling and operating conditions to prevent damage. Address issues promptly to avoid motor failure and maintain efficient pump performance.

Understanding Error Codes

Modern pool pumps often display error codes to indicate specific issues. Codes like E01 or E02 typically relate to pressure‚ flow‚ or electrical problems. Refer to your manual for code meanings‚ as they vary by manufacturer. Addressing these codes promptly prevents further damage. Common causes include clogged filters‚ incorrect wiring‚ or sensor malfunctions. Always follow the manual’s troubleshooting guide to resolve issues efficiently and ensure safe‚ optimal pump operation.

Safety Guidelines and Precautions

Always follow electrical safety measures‚ install lockable fences‚ and ensure proper grounding to prevent accidents. Adhere to local codes and manual instructions for safe pool pump operation.

Electrical Safety Measures

Always follow the manual’s electrical guidelines and local codes. Install GFCI breakers and ensure proper grounding to prevent shocks. Regularly inspect wiring and avoid overloaded circuits. Keep the pump area dry and avoid electrical components near water. Never operate the pump with damaged cords or exposed wires. Ensure all connections are secure and meet safety standards to protect against hazards. Proper electrical setup is crucial for safe and efficient pool pump operation.

Pool Fence and Barrier Requirements

Installing a sturdy pool fence is crucial for safety‚ especially to prevent accidental drownings. Ensure the fence is at least 4 feet tall and equipped with a self-latching‚ self-closing gate. Check local codes for specific requirements‚ as some areas mandate taller fences or additional barriers. Regular inspections are essential to maintain the fence’s integrity and ensure compliance with safety regulations. A secure pool barrier helps protect children and pets from potential hazards.

Energy Efficiency and Cost Savings

Optimizing your pool pump’s runtime and using variable speed pumps can significantly reduce energy consumption‚ leading to lower utility bills and environmental impact while maintaining pool cleanliness.

Optimizing Pump Runtime

Optimizing your pool pump’s runtime reduces energy costs and extends its lifespan. Adjust the runtime based on pool size‚ usage‚ and filtration needs. Running the pump for shorter‚ consistent periods can maintain cleanliness without overconsumption. Consider using programmable timers to automate operation during off-peak hours. This approach ensures efficient energy use while keeping your pool clean and safe‚ aligning with the manual’s recommendations for cost-effective maintenance.

Using Variable Speed Pumps

Variable speed pumps offer flexibility and energy efficiency by adjusting speeds to match specific tasks. Unlike single-speed models‚ they operate quietly and use significantly less energy‚ especially during low-demand periods. By following the manual’s guidelines‚ you can program multiple speed settings for filtration‚ cleaning‚ and water features. This customization reduces wear and tear while lowering electricity bills‚ making variable speed pumps a cost-effective and modern choice for pool maintenance.

Regular Maintenance and Upkeep

Regular maintenance ensures optimal pump performance and longevity. tasks include cleaning filters‚ inspecting for wear‚ and lubricating moving parts‚ preventing unexpected breakdowns and costly repairs.

Scheduled Maintenance Tasks

Regularly inspect and clean the filter to ensure proper water flow. Check the pump and motor for wear or damage. Lubricate moving parts as specified. Inspect electrical connections and ensure they are secure. Replace worn seals or gaskets promptly. Schedule monthly visual inspections of the entire system. Maintain a log of maintenance activities to track performance and identify potential issues early. This routine helps prevent breakdowns and extends the pump’s lifespan‚ ensuring efficient pool operation year-round.

Winterizing the Pump System

Drain the pump and associated pipes to prevent freezing. Disconnect hoses and store them in a protected area. Use a drain adapter to keep pool flaps secure during draining. Blow out lines with compressed air if necessary. Inspect and store small parts like O-rings and gaskets. Follow manufacturer guidelines for winter storage to avoid damage. Regularly check for any needed repairs before reopening the pool in spring. Proper winterization ensures the pump system remains functional and ready for the next season.

Refer to manufacturer guides for detailed troubleshooting and maintenance tips. Explore online forums for user experiences and expert advice. Ensure compliance with local safety codes for optimal pump performance and longevity.

Final Tips for Pump Longevity

Regularly inspect and clean the pump basket and filter to ensure optimal flow. Lubricate moving parts as recommended to reduce friction and wear. Maintain proper water chemistry to prevent corrosion and scaling‚ which can damage the pump over time. Schedule annual professional inspections to address potential issues before they escalate.

Invest in energy-efficient models like variable speed pumps to reduce runtime and lower operational costs. Keep the pump motor shaded to protect it from direct sunlight and extreme temperatures. Avoid overloading the pump‚ as this can lead to premature failure. By following these tips‚ you can extend the lifespan of your pool pump and ensure consistent performance.

Recommended Further Reading

For deeper insights‚ explore manufacturer-specific manuals‚ such as Hayward or Pentair guides‚ which offer detailed troubleshooting and maintenance tips; ENERGY STAR resources provide guidance on energy-efficient pump selection. Pool industry blogs and forums share real-user experiences and solutions. Additionally‚ local pool supply stores often offer workshops on pump maintenance and optimization. These resources complement this manual‚ ensuring comprehensive understanding and optimal pump performance for years to come.

About the author